Contact

You have any questions?

Or want us to call you?

By using our online form your questions and requests will be forwarded to the responsible contact person.

...to the form

Edge trim exhaust

Tailor-made continuous conveying

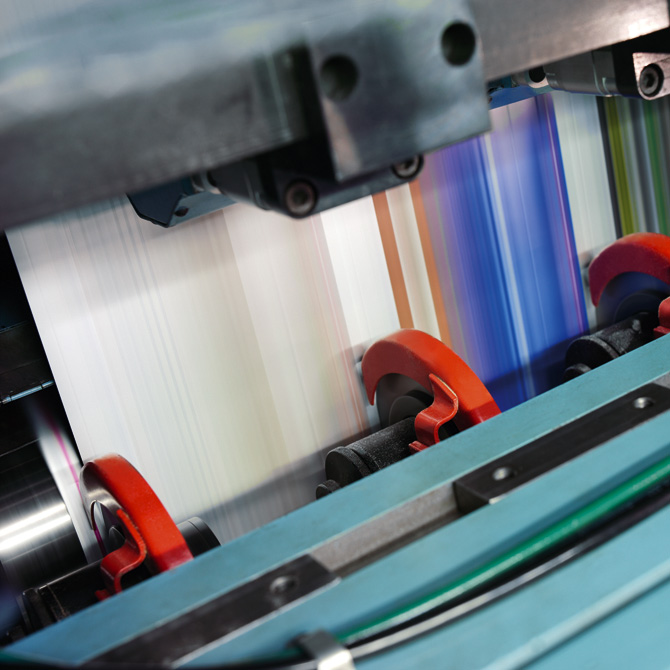

Venti offers tried and tested and efficient solutions to collect, transport and dispose of edge trim waste, produced during the cutting or trimming of continuous material.

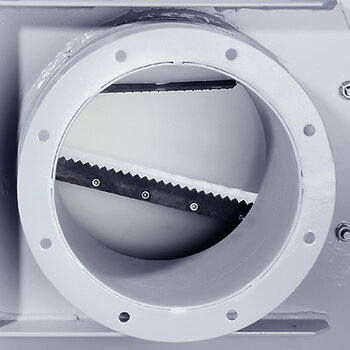

We design and construct material trapping devices in collaboration with leading machine manufacturers and operating personnel. The material is conveyed by special fan impellers designed for shredding through the pipe network to the separator. Various techniques ensure that edge trims are effectively and efficiently shredded during transport even if they occur intermittently. Tearing fans, pipe cutters and cutting mills are therefore also included in the Venti system solutions.

The selection of appropriate pipe cross-sections and the optimised configuration of pipework reduce energy costs and guarantee problem-free operation. The technical specialists at Venti Oelde employ computer-aided simulations for the individual design of custom solutions for every system. We install everything from switching systems, monitoring and control technologies, as well as control systems for split-second rerouting of material flows to safetyrelevant components andswitchgear.

It goes without saying that Venti Oelde also offers isolated solutions for individual machines. Standard injector systems transport the endless strips to a recovery container or a recycling plant

![[Translate to English:] kopf-produkte](/fileadmin/_migrated/media/Kopf_produkte_091001.jpg)

![[Translate to English:]](/fileadmin/user_upload/teaserbild-anfrage_v2_07.png)