Contact

You have any questions?

Or want us to call you?

By using our online form your questions and requests will be forwarded to the responsible contact person.

...to the form

Jet bag filter

Reliable performance for problem dust

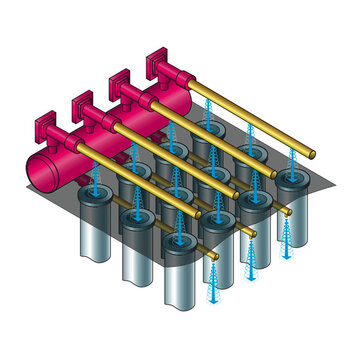

Special separation systems are required for very fine dust. The same is true for fibrous, sticky or moist dust, or for dust which is difficult to agglomerate. Processes with a high concentration of dust and material require filter systems which continue to work reliably when the filter surfaces are subject to maximum loading. Venti Oelde filters do everything you would expect of a modern filter system. Venti Oelde offers a single or double row filter, depending upon the amount of air, the amount of dust it carries and upon the space available. All filters can be used as suction and as pressure filters. The double row designs are arranged with a centrally located inlet corridor for the unfiltered gas.

The gas to be filtered is fed to the outside of the filter bags in Venti Oelde’s industrial filters. The bags are intensively cleaned with pulses of compressed air during normal operation, synchronised to the operation in progress. To avoid adhesion and blockages with lightweight, fibrous materials, we enlarge the filter bag spacing and additionally include cleaning for the space between the bags.

As required, we make our industrial filters in galvanised, painted or stainless steel, with a minimum wall thickness of 3 millimetres for the housing. They are suitable for use both indoors and out.

We make our filters using sophisticated modular technology, consisting of bent and bolted wall components. If minimum leakage is required, we can also seal the housing by welding from the inside. The filters are available in a range of heights and are designed for differing bag lengths and varying pressure levels.

More detailed information about jet bag filter

Exhaust plants for flame-cutting smoke

brennschneid-13-en_01.pdf

Exhaust plants for flame-cutting smoke

brennschneid-13-en_01.pdf Exhaust, filter and convey

absaug-entst-foerd-en.pdf

Exhaust, filter and convey

absaug-entst-foerd-en.pdf Dedicated solutions for the printing and paper industries

drupa-en.pdf

Dedicated solutions for the printing and paper industries

drupa-en.pdf Dedicated solutions for the woodworking industries

holz-en.pdf

Dedicated solutions for the woodworking industries

holz-en.pdf Specialized solutions for the recycling industry

recycling-16-en_01.pdf

Specialized solutions for the recycling industry

recycling-16-en_01.pdf Specialized solutions for the iron and steel, metal-working and processing industries

metall-2015-en_01.pdf

Specialized solutions for the iron and steel, metal-working and processing industries

metall-2015-en_01.pdf Industrial filters

industriefilter-2015-en_02.pdf

Industrial filters

industriefilter-2015-en_02.pdf

![[Translate to English:] kopf-produkte](/fileadmin/_migrated/media/Kopf_produkte_091001.jpg)